Core Advantages of Variable-Frequency Three-Phase Induction Motors in Industrial Applications

作者:臥龍南陽防爆電機(jī)時間:2025-11-27 09:02:40 次瀏覽

信息摘要:

In the era of rapid industrial automation development, variable-frequency three-

In the era of rapid industrial automation development, variable-frequency three-phase induction motors have become a standard configuration for numerous enterprises. Compared to traditional power frequency motors, they offer significant advantages in energy efficiency, control precision, and operational stability—making them widely used in fans, water pumps, conveyor systems, crushers, mixing equipment, and other industrial scenarios. For businesses still considering equipment upgrades, understanding the core benefits of variable-frequency (VF) three-phase induction motors is crucial.

1. Stepless Speed Regulation: On-Demand Output & Energy Savings

The most distinctive feature of VF motors is their ability to achieve stepless speed regulation. Once traditional power frequency motors start running, their speed remains essentially fixed, unable to flexibly adjust to changes in on-site load. This results in wasted electricity under light loads and a high risk of overheating under heavy loads. In contrast, VF three-phase induction motors adjust speed in real time based on operating conditions by regulating frequency via a frequency converter, enabling true "on-demand output" and drastically improving energy utilization efficiency. In fan and water pump applications—where load variability is common—energy savings can typically reach 20%-40%, delivering substantial cost reductions for enterprises.

2. Comprehensive Protection: Enhanced Operational Reliability

VF motors also boast superior protection capabilities. Frequency converters themselves integrate multiple protection functions, such as overload protection, overcurrent protection, and undervoltage protection. When paired with a VF motor, these features make equipment operation safer and more reliable, effectively reducing the risk of downtime caused by motor failures. For continuous-production industries—including mining, cement plants, and chemical factories—operational stability often takes precedence over pure efficiency. This is one of the key reasons VF three-phase induction motors remain highly favored.

3. Reduced Mechanical Shock: Extended Equipment Lifespan

Traditional motors draw starting currents that can reach 5-7 times the rated current when starting directly, which easily impacts the power grid, the motor itself, and the driven equipment. VF soft starting, however, controls the starting current to approximately 1.5-2 times the rated current. This gentler startup minimizes mechanical shock, prolonging the lifespan of critical components such as bearings, couplings, and reducers—while also lowering long-term maintenance costs.

4. Intelligent Integration: Aligned with Industrial IoT Trends

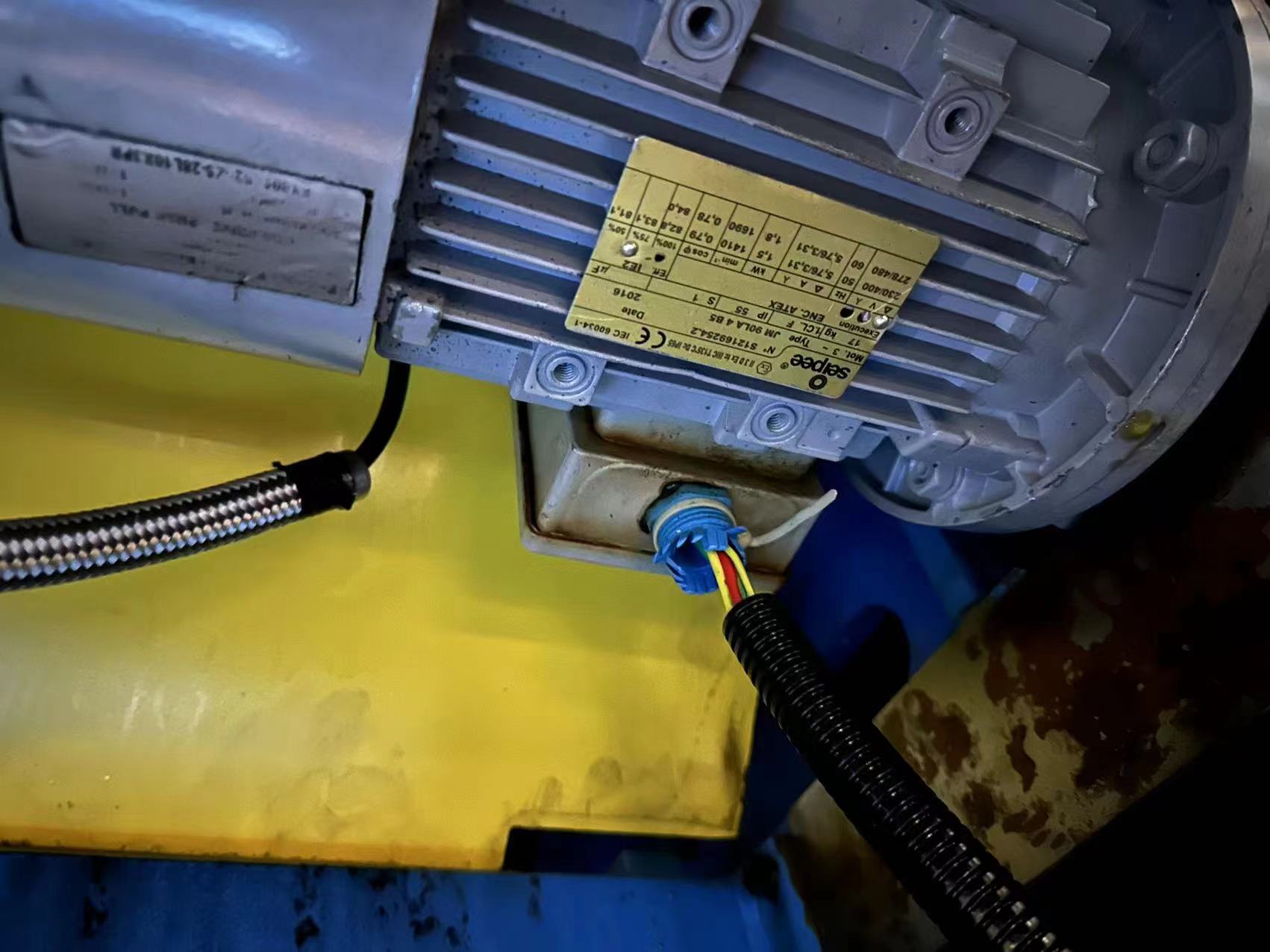

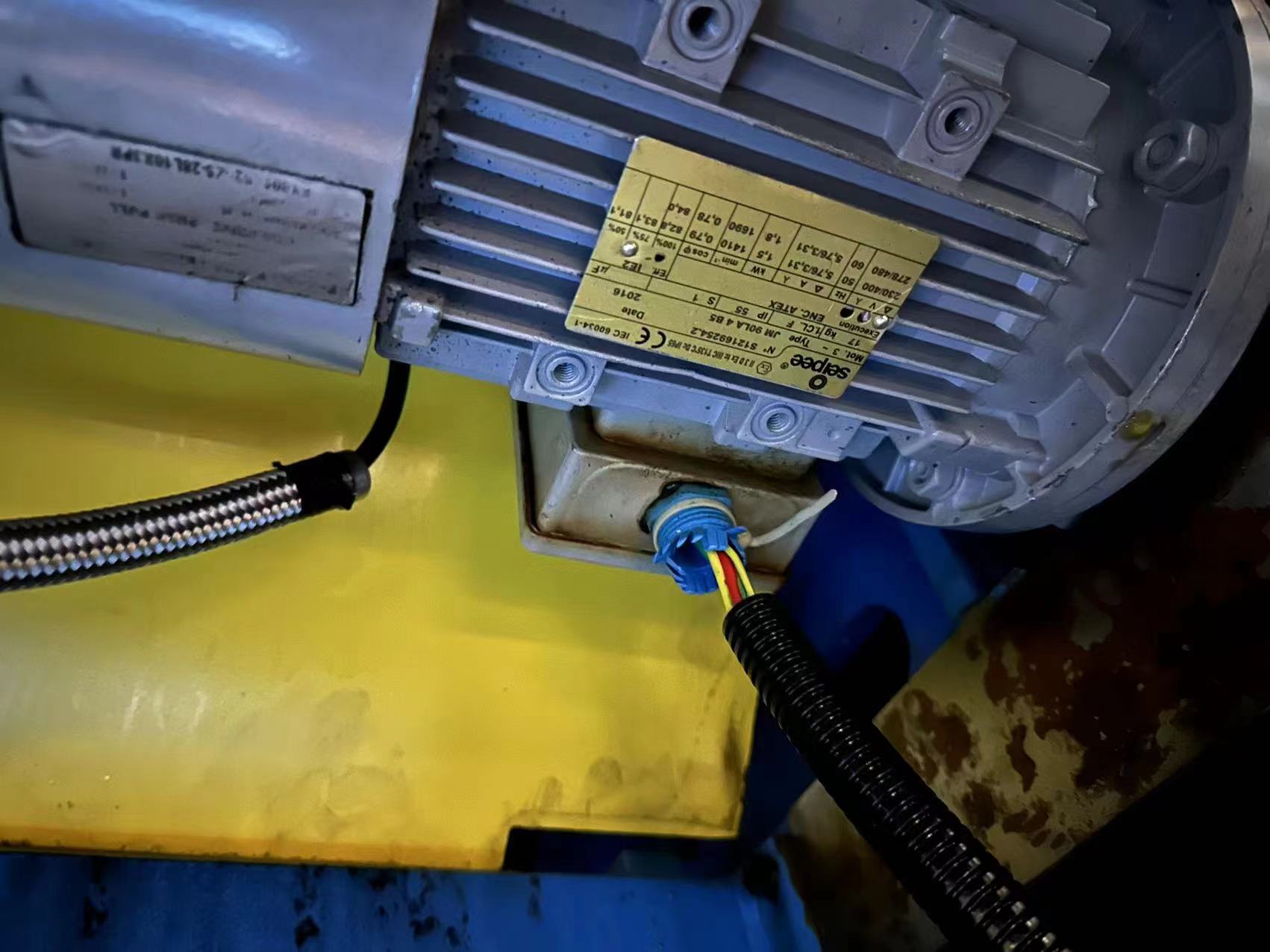

As the Industrial Internet of Things (IIoT) gains momentum, more enterprises are adopting motors equipped with real-time monitoring of temperature, vibration, current, and other operational data. VF systems inherently feature communication capabilities, allowing seamless integration with automation platforms. This enables enterprises to track equipment health in real time and conduct predictive maintenance, preventing unexpected failures and optimizing production schedules.

For businesses seeking to improve production efficiency and reduce energy consumption, adopting VF three-phase induction motors has become an inevitable trend. Whether for new projects or retrofitting existing equipment, these motors deliver tangible energy-saving benefits and more stable operational performance—driving sustainable development and competitive advantages.

The Future of Wolong’s Permanent Magnet Direct-Drive Motors

簡體中文

簡體中文